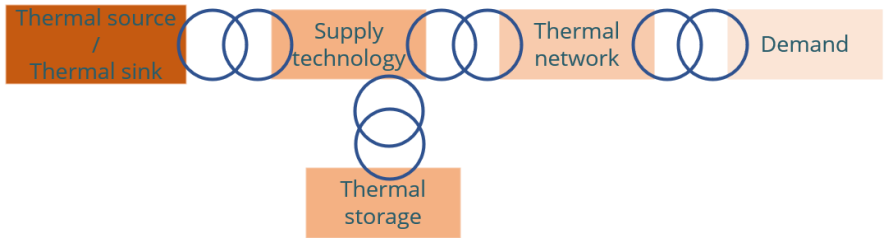

LTDH

- Space heating and domestics hot water demand can be covered directly without temperature boosting

- Substations use traditional technologies and concepts

- Relatively simple design and operation Investment relatively small

- Bi-directional energy exchange with thermal network is not possible

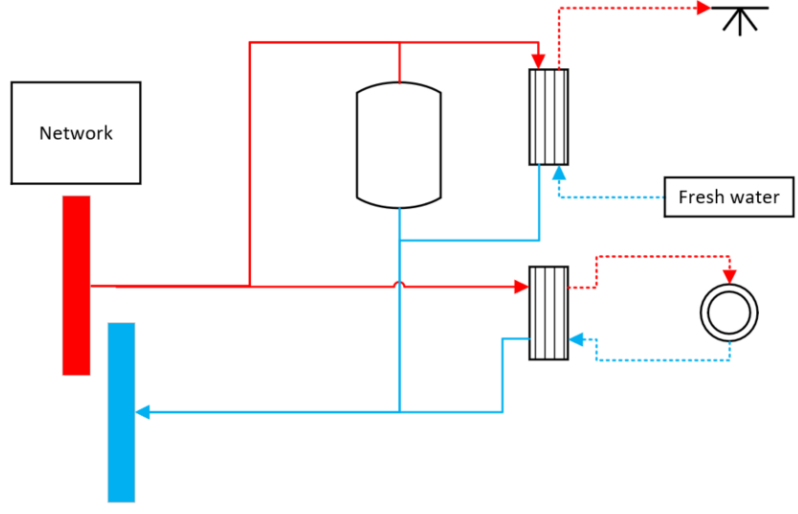

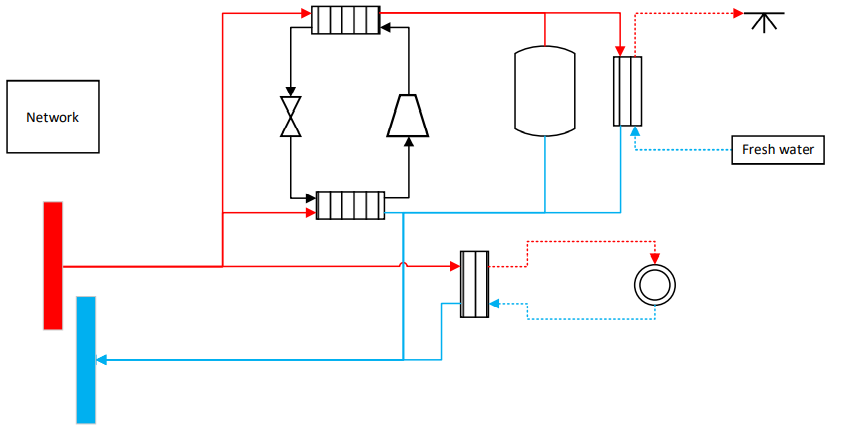

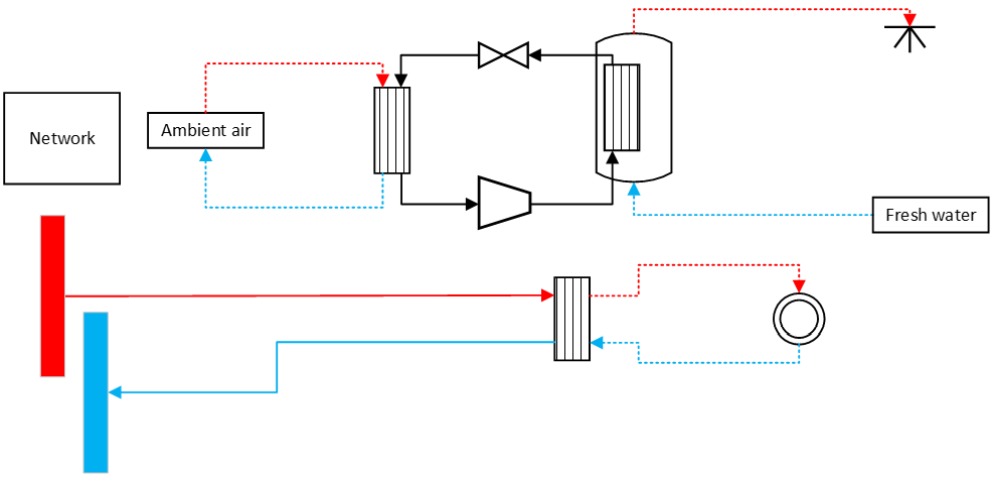

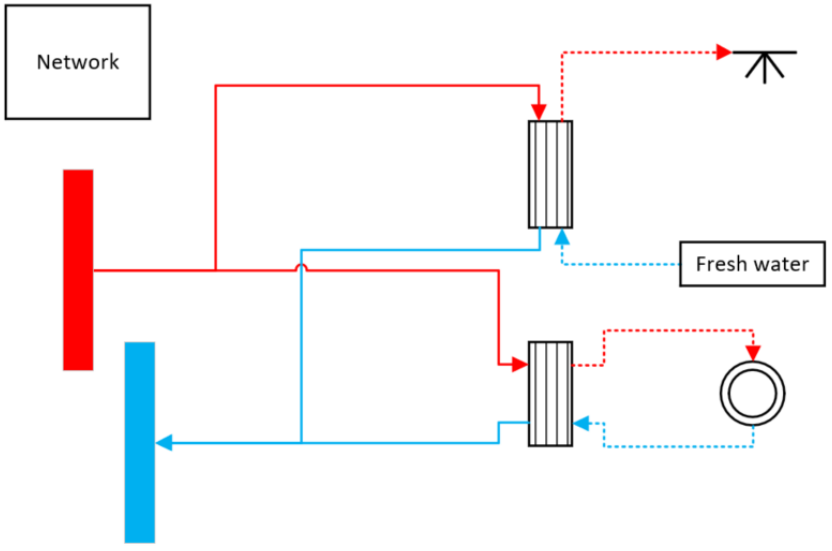

LTDH substation – instantaneous heat exchanger unit

This LTDH substation is based on instantaneous heat exchanger unit.

It is highly efficient and compact heat exchanger capable of

providing domestic hot water on-demand.

Strengths

- Low-space consuming

- Cost-effective

Weaknesses

- DHW production on demand (no TES available)

Opportunities

- Easily upgradeable

Threats

- System flexibility is reduced

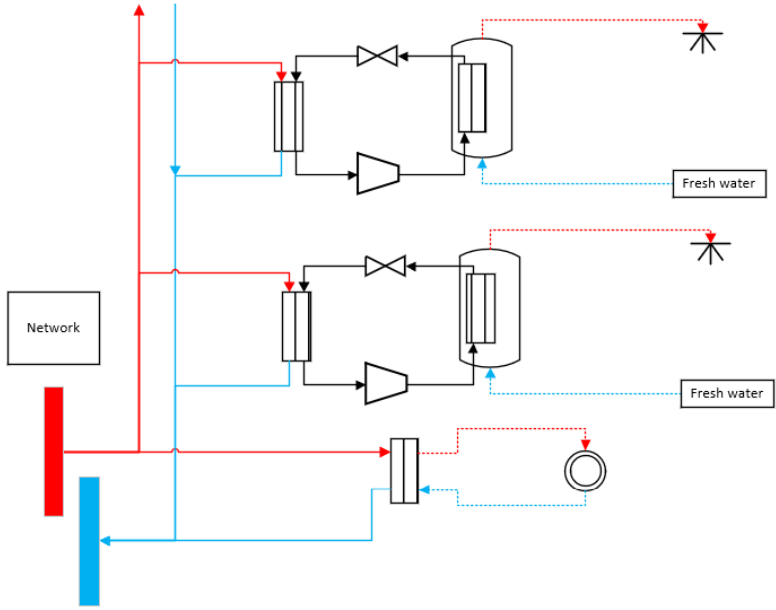

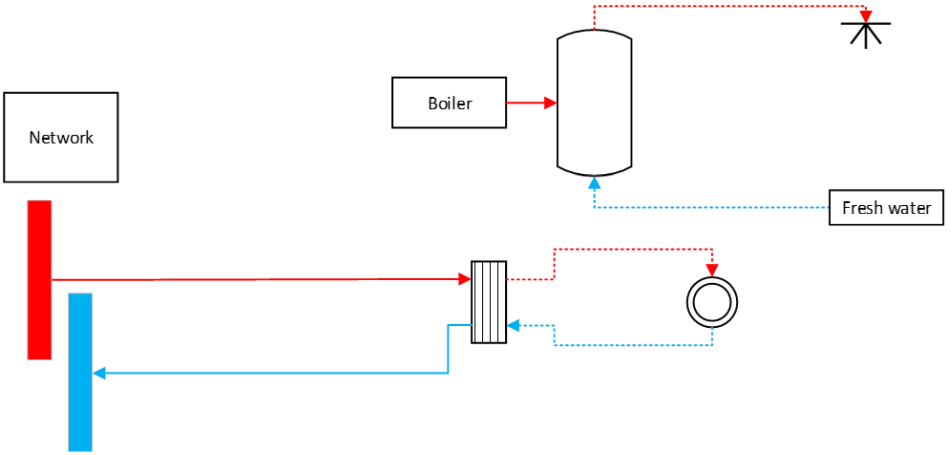

Second LTDH substation is based on district heating storage unit. Due to water stagnation, temperature regimes must be higher that with IHEU. This solution demands higher volume for installation of district heating storage tank. Besides thermal storage unit, heat exchangers are needed domestic hot water and space heating demand.

Strengths

- Increased flexibility (TES available on-site)

Weaknesses

- TES investment needed

- Additional space is needed in the building

Opportunities

- asily replaceable with different space-demanding solution

(booster heat pump)

Threats

- Higher temperature is needed due to stagnated water

(Legionella risk)